Kapa panels - Lightweight, stable and versatile

Kapa sheets are the ideal solution for creative projects, professional presentations and high-quality displays. With their low weight and amazing stability, they are among the most popular materials in advertising technology, model making, museums and trade fair and exhibition construction.

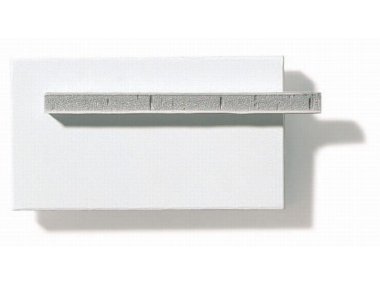

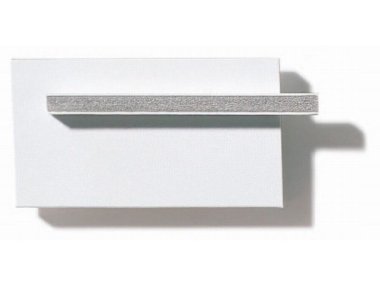

Smooth on the outside, foam on the inside

Kapa panels are stable composite sheets: The panels are a multi-layered material made from two different, firmly bonded materials. Kapa panels are more resistant than other laminated sandwich panels. This is due to their core of solvent-resistant polyurethane foam. During production, this foam is not cut from the block and then laminated, but foamed between the surface layers. This provides many advantages:

- Ultra-light and yet dimensionally stable: the polyurethane rigid foam core ensures high flexural rigidity with minimum weight. This is ideal for large-format applications.

- Perfect for printing and processing: The paper or cardboard cover layers on both sides provide the perfect base for digital or screen printing, foil labelling or painting.

- Simple further processing: Kapa sheets can be cut, routed or drilled effortlessly - even without special tools.

- Clean edges and high dimensional stability: Precise cuts and exact fits are no problem with Kapa sheets.

Which Kapa panel for what?

Kapa panels are available from Modulor in different versions - depending on your requirements:

Kapa line

is the standard version with a paper top layer. These boards are perfect for simple applications and presentations. They are available in different sheet thicknesses from 3mm to 15mm and five different sheet sizes.

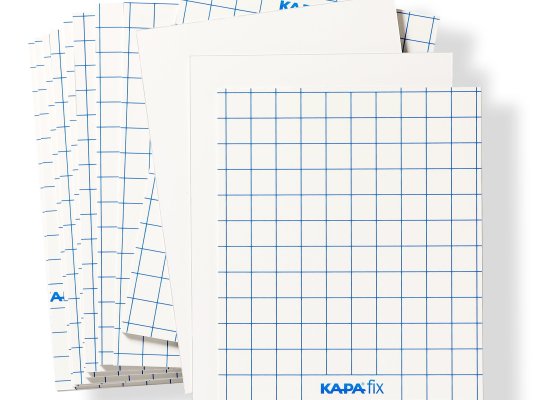

Kapa Fix

With its self-adhesive surface, Kapa fix is ideal for quickly mounting prints and images. This variant is available in both single-sided and double-sided self-adhesive versions. You can choose between three different sheet thicknesses and sizes.

Kapa plast

sheets have a plastic top layer. This makes this variant particularly stable and moisture-resistant. In addition to three different sheet thicknesses from 3mm to 10mm, the sheets are available in five sizes up to 2030 x 3050mm.

Kapa Graph

The top layer of Kapa graph is particularly smooth. This makes this sheet particularly suitable for digital printing. These sheets are available from Modulor in white and black. Options: Two thicknesses (3 mm and 5 mm) and two sizes (width × length: 700 mm × 1000 mm or 1000 mm × 1400 mm).

Not sure which Kapa panel is right for your project? In the Kapa sample box you will find ten samples of all standard Kapa boards cut to size in A5 format so you can get your own overview.

Versatile application

Kapa sheets are perfect when it comes to lightweight, stable and versatile sheet materials. Whether for advertising signs, presentation walls or model making - Kapa is easy to process, can be cut to size precisely and presented professionally. The material properties of Kapa sheets determine their typical areas of application:

- As they are particularly lightweight and can be optimally printed or glued on, they are ideal for temporary advertising signs, POS displays or ceiling hangers indoors.

- Their high dimensional stability and uncomplicated processing make them perfect for flexible exhibition walls, product carriers or decorative elements.

- The Kapa sheets can be cut and moulded precisely. This is ideal for the detailed realisation of prototypes or models in the fields of design, architecture and model making in general.

- Kapa is also a popular choice for laminating photos, prints and art prints - thanks to its smooth surface and clean cut edges. Kapa boards can even be used as a simple pinboard.

- In scenery and stage construction, large formats and low weight are in demand. Accordingly, Kapa is ideal for stage sets, backdrops or props in the theatre and event sector.

- Kapa panels can also be used as back walls or displays at trade fairs or for presentation purposes. As lightweight panels, they are also easy to move and transport.

How to work with Kapa sheets

Whether cutting, bending, gluing, laminating or printing and varnishing - your Kapa sheets can be easily processed even without special equipment. We have summarised the most important tips for you here:

Cutting to size:

A simple cutter, which should be held as horizontally as possible, is sufficient for cutting a Kapa sheet to size. Our Foamwerks straight/angled cutters also allow angled cuts. Power tools such as a fine-toothed circular saw are also suitable for processing. You can use jigsawsscroll saws and for round cuts. Drill holes with circular cutters or hole drills. Avoid using scissors and laser cutters. They cause unclean cutting edges.

Gluing:

Thanks to their hard foam core, Kapa boards are largely resistant to solvents and can be processed well with all-purpose glue or other adhesive varnishes. The same applies to double-sided adhesive tape or transfer adhesives.

Printing, laminating and varnishing:

Kapa boards can be printed using screen or digital printing (flatbed printer). The solvent-resistant polyurethane foam core also allows processing with solvent-based inks. For full-surface application (painting, spraying) or when using emulsion paints, it is recommended to use the aluminium-reinforced Kapa mount sheets to prevent the sheets from warping. The self-adhesive Kapa fix board is best suited for laminating, i.e. mounting pictures and photos. You should make sure that you work as dust-free as possible.

Incidentally, we recommend the metal hangers for foam boards for hanging.

Alternatives to Kapa panels

From an environmental and aesthetic point of view, cardboard honeycomb panels are an interesting alternative to Kapa panels. Depending on the intended use, thick solid or corrugated cardboard, Forex or Dibond, plastic sheets (e.g. polystyrene) or other sandwich panels can also be used.