E2 table Frame

Anyone who deals with the subject of desks can hardly avoid the E2 table frame. Even after many years, we are still enthusiastic about the design: four legs + one connection. The Eiermann design is the essence of a table frame - a pure supporting structure, reduced to slender steel tubes, it couldn't be more timeless.

Configure your E2 table - or simply your E2 table frame

In our configurator, you can put together an E2 table according to your wishes. At the same time, you immediately see a 3D visualisation of the table. You specify the dimensions, select surfaces and add accessories. Every change is immediately incorporated into the configuration. We show you the complete price for your customised Eiermann table transparently at all times.

If you only want to order the Eiermann or E2 table frame, you can also do this directly via the configurator. Please select the "None" checkbox under the "Top" selection. You can also change the size of the E2 table frame in this presetting via the first item "Dimensions". The dimensions then set describe a "theoretical" table top, so to speak. n the configuration, this is displayed transparently.

You also have the option "Only show variants available for immediate delivery". Here you will only see the Eiermann desks that are available for immediate delivery. Even with this selection, you can do without the table top as shown above. We have all the fast-delivery versions in stock. We can deliver orders immediately.

The right E2 table frame for you

Select side parts of the E2 table frame

The side sections are made up of table legs and the cross struts that connect the legs in pairs. Welded together at right angles, they form an "H with two crossbars", so to speak. The side sections of the E2 table frame are available in six sizes. When selecting the side parts, it is important to decide whether you want an E2 table frame with a central or an offset cross strut. The holes for connecting the side sections and cross struts are not provided for both variants in each side section. We recommend offset cross struts for a work table, for example. For a table placed freely in the room and used from both sides, on the other hand, central cross struts are important. Therefore, if you later wish to offset the cross struts, for example, you would have to get other side panels.

The cross struts of the E2 table frame

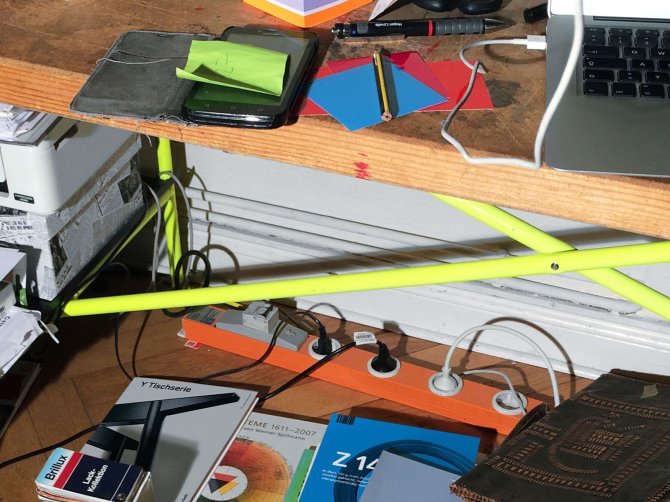

The diagonally crossing connecting struts are characteristic of the E2 table frame. They connect the side sections to each other and hold them in position. This principle is also familiar from shelving units, where a cross on the back often provides stability. With the E2 table frame, however, the connecting cross is the iconographic element that makes the Eiermann design so recognisable. When buying an Eiermann table frame, you basically have to decide whether the side sections should be centred or offset on the side sections. The cross struts are the same for both variants. However, you also have to make a choice for the cross struts: They are available for the E2 table frame in two lengths for different table widths.

Grows with you: The E2 children's table frame

The E2 children's table frame is a slightly smaller Eiermann frame. Its size is adapted to children's needs. However, the height adjusters make it a lifelong companion, as the table height can be adjusted from child-friendly size to adult level. And if only a laptop and a hot drink need to be placed on it, the table top is also sufficient. You can even fit a magazine on the table.

FAQ

The standard height of work tables is between 74 and 76 cm. The E2 table frame achieves this table height (upper edge of table top) without height adjusters: a table frame with 72 cm high side sections and a 2.5 cm thick table top result in a total height of 74.5 cm. However, the lower frame with a height of 66 cm with additional height adjusters also comes to the standard height. So the question is whether you want a flexible table height for your E2 table or whether the table height should be fixed.

Unfortunately, a standard size does not fit everyone equally well. The standard table height specified above (74 cm - 76 cm) is tailored to people between 1.70 m and 1.85 m tall. But firstly, everyone's proportions are different and secondly, the table height is also related to the seat height. The ISO 5670 standard provides information on seat and table heights. A height-adjustable chair allows you to sit in a comfortable and ergonomic position. You don't have an adjustable desk chair? In this case, first measure the seat height and select the desk height so that you have 27 cm - 32 cm of space between the lower edge of the table top and the seat. This allows you to cross the legs under the table if necessary.

With the E2 table frame, there are two options for connecting the side sections to the cross struts. They can be attached in the centre of the side sections or offset in the direction of the depth of the table frame. We only recommend a central cross for tables that are to be used from both sides. Work tables, on the other hand, are usually only used from one side. The offset cross provides noticeably more legroom here and is therefore the ideal choice. To illustrate this, the configurator drawings show schematised side views of the table frame when selecting "Cross struts" above the terms "Central" and "Offset".