Acrylic Sheets – versatile, lightweight and shatterproof

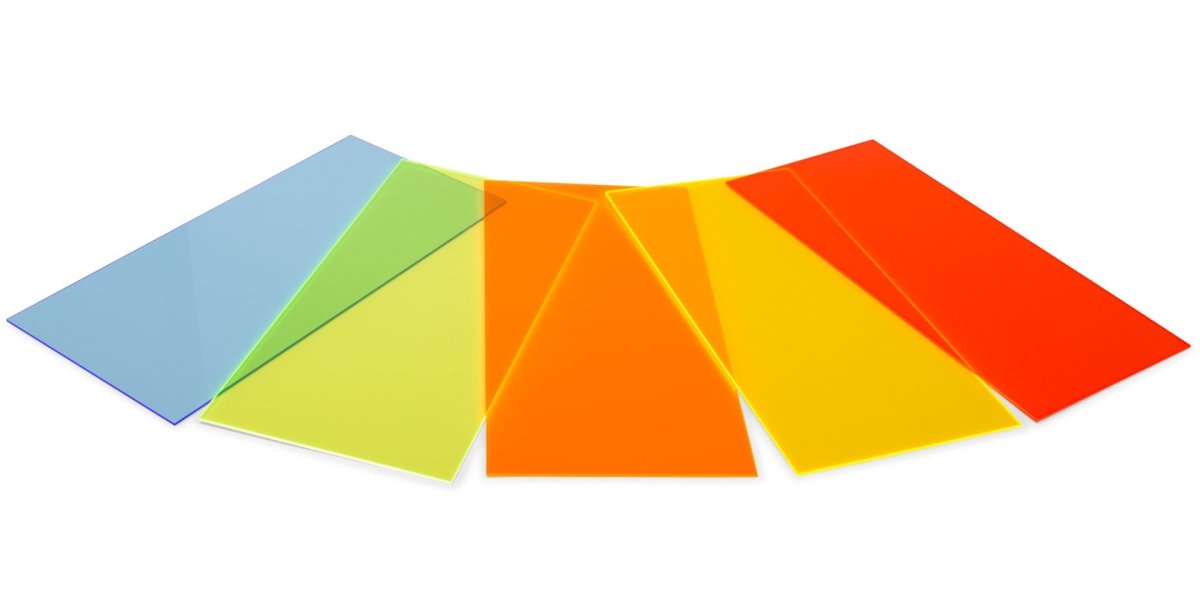

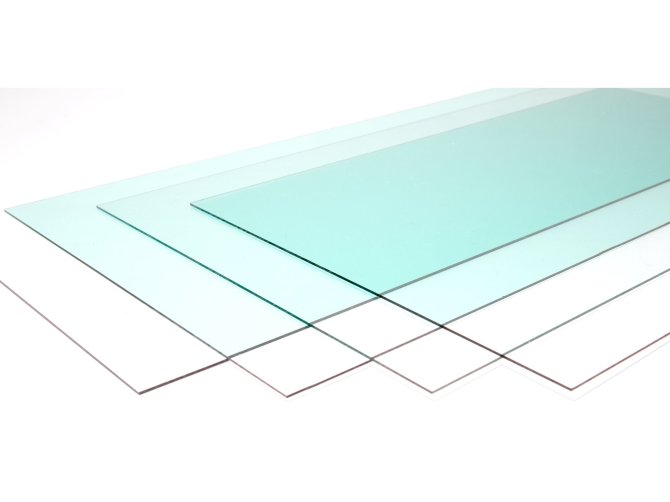

Discover the wide range of acrylic sheets at Modulor! Whether transparent, coloured or satin-finished, acrylic glass (PMMA) is the ideal substitute for glass. It is lighter, shatterproof and available in a variety of designs. Perfect for trade fair construction, furniture and all kinds of design projects.

Acrylglas-Platten – die Glas-Alternative für innen und außen

Acrylic glass is the catchier name for polymethyl methacrylate (PMMA). This synthetic polymer is stable at temperatures between -40 °C and 70 °C. When heat is applied, it can be moulded from 150 °C and has a melting point of 160 °C. As part of building material class B2, acrylic glass is considered normally flammable, with a few exceptions.

Acrylic glass is a fantastic alternative to conventional glass. Compared to the latter, the plastic panes are almost half the weight. In addition, there are further advantages such as the higher light transmission and weather resistance as well as the flexibility of the plastic glass. In addition, acrylic glass is comparatively easy to process thermally and mechanically. With its numerous appearances, from transparent, opaque or satinised, to colour variations and design as sheets, rods or blocks, this art glass has limitless application possibilities.

Acrylic glass and PLEXIGLAS® sheets enable a safe yet crystal-clear presentation of exhibits and sales items in trade fair, display and shop construction. In combination with light sources, coloured and transparent plastic sheets create a particularly atmospheric effect. In furniture construction, acrylic glass is used for lightweight constructions such as light screens, organisation systems, storage compartments, picture frames, aquariums and much more. The transparent and functional properties of plastic glass sheets complement each other wonderfully when used to cover tables and as splash protection in kitchens and workshops.

The weather-resistant acrylic glass sheets can also be used outdoors without hesitation. As panelling or wind protection on balconies, in conservatories, on fences and stair railings, they are both functional and aesthetically pleasing. As advertising signs, they are the modern figurehead of agencies, surgeries and offices.

Acrylic glass GS - Moulded plastic glass

Acrylic glass GS is the cast and therefore high-quality version of artificial glass. It is easier to machine and thermally mould. To produce acrylic glass GS sheets and blocks, liquid PMMA is polymerised between two glass sheets. The resulting material is unbreakable, weather-resistant, highly transparent and easy to process. Acrylic glass GS can be easily further processed using a milling cutter, drill and saw. The cast plastic glass can be moulded at temperatures between 160 °C and 180 °C. We recommend cast precision acrylic glass especially for fine milling work such as in model making.

Acrylic glass XT - the favourable alternative

Acrylic glass XT is what is known as extruded art glass. During its production, granulate is melted and drawn into shape using an extruder. It is slightly cheaper than acrylic glass GS. The XT plastic variant is available both as thin sheets and in the form of rods, tubes, spheres and cubes. In contrast to cast acrylic glass, XT acrylic glass in sheet form is somewhat more dimensionally stable and has lower thickness tolerances. It melts more quickly during processing, can smear drills and saws and has a clearer cutting edge. Machining is also somewhat more difficult with acrylic glass XT. Accordingly, this extruded material is more suitable for work that involves little drilling, milling and turning.

On the other hand, its polymer structure makes it easier to bond with solvents such as dichloromethane or special plastic adhesives such as Acrifix.

In terms of surface quality, visible transparency and resistance to weathering and ageing, acrylic glass XT is in no way inferior to the cast GS version. We recommend the cheaper XT acrylic glass in particular for glazing, picture frames, simple model making and wherever unprocessed surfaces are used.

Precision acrylic glass - for displays and modelling

Precision acrylic glass is a moulded plastic sheet. They are characterised by extremely low thickness tolerances (± 0.1 mm for sheets up to s=1.0 mm, ± 0.2 mm for sheets from s=1.5 mm). In contrast to other cast acrylic glasses such as PLEXIGLAS® GS, these precision glasses are available from a thickness of 0.5 mm upwards. All sheets are manually checked by the manufacturers for thickness tolerances and optical defects.

Precision acrylic glass can be manufactured in numerous colours and various surface textures despite very low production quantities. Sheet thicknesses between 0.3 mm and 4.0 mm are available.

In consumer electronics and medicine, precision acrylic glass is often used to cover displays. It is perfect for precise milling and drilling work in model making. From model parts such as lightly coloured and flat glass facades to entire architectural models, the precision plastic sheet is versatile.

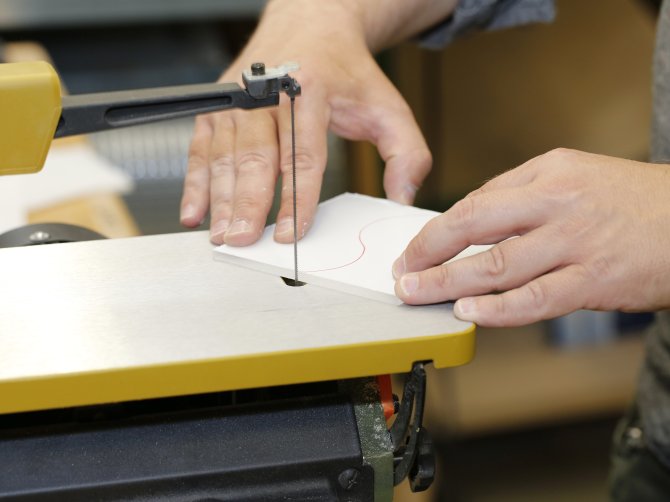

Recommendations for processing acrylic glass

Circular table saws, jigsaws and routers with fine-toothed saw blades as well as lasers are suitable for processing plastic glass sheets. In order to achieve the most transparent cut edges possible, it is advisable to add a little washing-up liquid, especially for modelling. High-gloss edges can be achieved by sanding and polishing. Art glass sheets up to a thickness of 3 mm can also be cut with an acrylic cutter. A clever alternative in this context is to score and break the glass several times on the edge of a table.

To clean acrylic glasses, we recommend warm water with washing-up liquid or a special plastic cleaner. Glass cleaning agents, on the other hand, can attack the plastic.

We recommend special plastic adhesives such as Acrifix, Ruderer or dichloromethane for bonding acrylic glass panels.

Acrylic glass sheets cut to size

We cut many of our acrylic and Plexiglas to size according to your wishes and ideas. Information on the minimum cutting dimensions, prices and instant cutting in the Modulor shop can be found on the product page of the respective plastic glass and on our page for customised material processing. Discover our entire range of acrylic glass cuts with a variety of colours, the wide range of different sheet thicknesses between 0.3 mm and 50 mm and sheet sizes up to 1.5 x 2.0 m.