Polymethyl methacrylate (PMMA) - The transparent plastic for versatile applications

Polymethyl methacrylate (PMMA) is a transparent, thermoplastic material that combines aesthetics, stability and versatility. Whether in mechanical engineering, architecture or design - it is hard to imagine modern applications without this acrylic glass.

The material

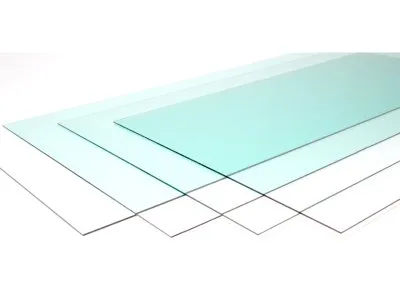

PMMA is also known under the brand name Plexiglas. The transparent plastic is characterised by the following properties:

- High light transmission (up to 92%) makes it ideal for crystal-clear applications. PMMA is also high-gloss.

- Its weather and UV resistance means that the acrylic glass does not yellow and retains its shape and colour for a long time, even outdoors.

- With its low weight, Plexiglas is about half the weight of conventional window glass.

- The high surface hardness of PMMA makes the material resistant to scratches. But acrylic glass also scores highly in terms of tensile, compressive and flexural strength.

- Thanks to its ease of processing, the plastic glass can be sawn, milled, drilled, lasered and thermoformed. Heat-resistant PMMA glass can even withstand temperatures of up to 95 °C for short periods.

- Polymethyl methacrylate has good chemical resistance. This means that it is resistant to many household cleaners, alcohol and oils, but is also food-safe

PMMA is used here

PMMA plastic glass is used in numerous areas. The material is popular in advertising technology and signage for the production of neon signs, displays and lettering. In the construction sector, acrylic glass is used for glazing roofs, windows and conservatories, as well as for industrial flooring and even bathtubs.

In interior fittings and furniture design, PMMA is ideal for translucent and mobile partition walls, as well as covers of all kinds. The material is also ideal for creating design elements.

Its surface hardness and chemical resistance are particularly important in medical and laboratory technology: Plexiglas is a recognised material for covers, protective screens, viewing windows, etc.

In vehicle construction, on the other hand, its light weight is favoured: light covers, visible parts and panelling made of PMMA are stable and transparent, but remain lightweight.

In the optical industry, watch glasses, magnifying glasses, optical fibres and photovoltaic systems are made from PMMA acrylic glass.

And polymethyl methacrylate has even found its way into private households. Transparent bowls, pens, cups, picture holders and so on are made from PMMA plastic glass.

Today, Plexiglas/PMMA is the ideal choice for translucent, dimensionally stable and durable plastic solutions. Thanks to its versatility in processing and design, it offers almost unlimited possibilities both in industry and in the creative sector.

Versatile processing options

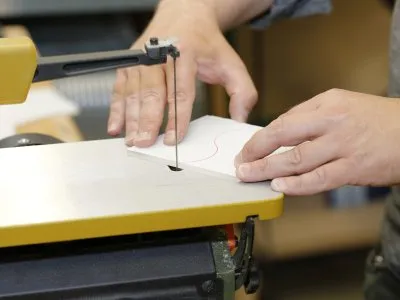

Whether professionally or as a hobby - PMMA is versatile and can be processed using standard methods, which often do not require any special tools.

Acrylic glass can be processed mechanically with saws, routers and drills or on lathes. Normal cutters are sufficient for cutting thin sheets. Straight cuts through thicker sheets can be scored. From a material thickness of 1.5 mm, however, you should use a carbide-tipped circular saw for cutting. Laser processing for precise cuts and engravings is also possible.

The material can also be thermally processed in processes such as hot bending, thermoforming and vacuum deep drawing. PMMA is particularly suitable for the thermoforming process: It can be easily moulded at temperatures as low as approx. 150 °C without losing its optical properties.

However, special adhesives and polishing pastes, polishing cloths and abrasive papers are required to produce permanently stable joints and for polishing. Dichloromethane is particularly suitable for bonding two acrylic glass surfaces. For larger bonding surfaces, the use of UV-curing reaction adhesives based on PMMA, such as Acrifix, is recommended. Dichloromethane can also be used to bond acrylic glass to other solvent-soluble thermoplastics such as polycarbonate or polystyrene. Silicone rubbers or contact adhesives can also be used to bond different materials.

Available forms on the market

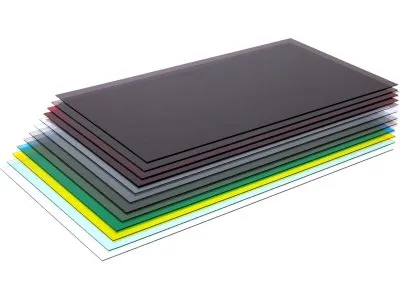

There are two basic types of PMMA available. "Acrylic glass XT" refers to extruded PMMA that has been pressed into shape using a mould. "Acrylglas GS" stands for cast PMMA parts. Its advantage: moulded acrylic glass is easier to work with. It is easier to saw or drill. Acrylic XT melts more quickly, sticks to the tools and leaves a white cut edge. However, acrylic XT is cheaper than cast acrylic glass.

PMMA is available in a variety of designs: sheets are available from transparent to opaque, satinised, coloured, extruded or cast. The sheet thicknesses range from 1 mm to over 25 mm. In addition to the standard sizes, you can also have them cut to your desired dimensions at Modulor. As tubes and rods, Acrlyglas XT in diameters from 1 mm to 25 mm is ideal for technical and design applications. Solid spheres up to 38.1 mm in diameter and cubes made of XT PMMA are available prefabricated from Modulor.

Cast PMMA is available in a wide range of colours and thicknesses, from thin and thick sheets to blocks. We can also cut or mill blocks and blanks to your individual requirements.

A little material history at the end

The plastic PMMA is better known in everyday life under the brand name Plexiglas. Inventor Otto Röhm marketed the transparent plastic under this name in 1933, but PMMA is also known as acrylic glass due to its excellent optical properties. Later, in 1956, the Braun company used acrylic glass for the first time in the manufacture of a record player cover. The designer Dieter Rams made the Phonosuper SK 4 model famous. Thanks to its transparent acrylic cover, the elongated radio-record player combination was later popularly known as "Snow White's coffin".