| Article No. |

|---|

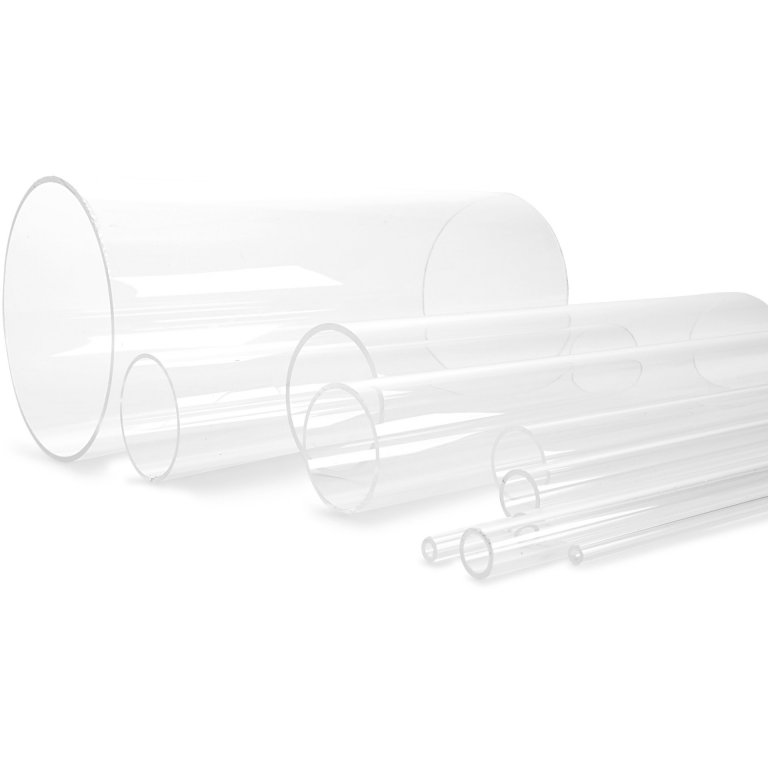

transparent, glossy, given dimensions: outer diameter x inner diameter

Acrylic tubes are produced in two different qualities: cast or extruded. Cast tubes are characterized by absolute freedom from streaks with high transparency and are excellent for machining. However, they are extremely expensive because their production is much more complex than in the extrusion process. In diameters up to approx. 60 mm, extruded pipes hardly differ externally from cast pipes, but they are more difficult to cut. In diameters of 150 mm and above, their quality sometimes leaves much to be desired in terms of transparency and freedom from streaks.

In addition to their use in architectural model making, acrylic tubes are also used in the manufacture of furniture, displays and decorations, as they are easy to bend when hot. They can be combined well with the tube connector system.

To prevent the tubes from buckling, they are tightly filled with sand before bending and sealed with plugs at the ends so that the sand cannot be displaced. After heating to forming temperature, bend in the bending jig. To avoid wrinkles on the inside edge of the bend, pull lightly on the ends of the tubes. To cut the tubes, simply saw them - with a metal saw blade that is only slightly set. If you do not want to saw yourself, we can also cut acrylic tubes to size on request. Please note the information under customization.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

| Article No. |

|---|

transparent, glossy, given dimensions: outer diameter x inner diameter

Acrylic tubes are produced in two different qualities: cast or extruded. Cast tubes are characterized by absolute freedom from streaks with high transparency and are excellent for machining. However, they are extremely expensive because their production is much more complex than in the extrusion process. In diameters up to approx. 60 mm, extruded pipes hardly differ externally from cast pipes, but they are more difficult to cut. In diameters of 150 mm and above, their quality sometimes leaves much to be desired in terms of transparency and freedom from streaks.

In addition to their use in architectural model making, acrylic tubes are also used in the manufacture of furniture, displays and decorations, as they are easy to bend when hot. They can be combined well with the tube connector system.

To prevent the tubes from buckling, they are tightly filled with sand before bending and sealed with plugs at the ends so that the sand cannot be displaced. After heating to forming temperature, bend in the bending jig. To avoid wrinkles on the inside edge of the bend, pull lightly on the ends of the tubes. To cut the tubes, simply saw them - with a metal saw blade that is only slightly set. If you do not want to saw yourself, we can also cut acrylic tubes to size on request. Please note the information under customization.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.