PLEXIGLAS® sheets: The versatile alternative to glass

Discover the limitless possibilities of PLEXIGLAS®! Whether transparent, coloured or satin - the lightweight and break-resistant glass alternative opens up fascinating perspectives for your indoor and outdoor projects.

What is PLEXIGLAS®?

PLEXIGLAS® is an acrylic glass that is known for its high quality and is offered with a guarantee of light transmission, hail resistance and non-yellowing. Visually and qualitatively, there are only minor differences to other types of acrylic glass. In common parlance, PLEXIGLAS® is often used synonymously for transparent plastic sheets, which can be traced back to the pioneering work of Otto Röhm in 1933.

Advantages of PLEXIGLAS® sheets

- Lightweight: Only half the weight of glass.

- Break resistance: Eleven times more break-resistant than glass.

- Weather resistance: Ideal for indoor and outdoor use.

- Machinability: Simple thermal forming (150 °C - 160 °C) and mechanical processing.

- Temperature resistance: Can be used from -40 °C to +70 °C.

Areas of application for PLEXIGLAS®

- Transparent: showcases, displays, picture frames.

- Translucent, coloured, satin: signs, light boxes, furniture doors and privacy screens

- Light guides: luminaires, light objects, illuminated advertising.

- Exterior applications: Balcony cladding, greenhouse glazing, exterior signage.

Buy PLEXIGLAS® online: Our offer

We offer PLEXIGLAS® sheets in various thicknesses (0.5 to 8 mm) and formats (from 120 x 250 mm to 1500 x 2000 mm). Our range includes transparent, translucent and opaque variants in numerous colours as well as milky white PLEXIGLAS® in various light transmission rates. We also stock non-reflective PLEXIGLAS® with UV protection for professional picture framing.

PLEXIGLAS® GS (moulded)

- Higher quality

- Ideal for drilling, sawing and milling

PLEXIGLAS® XT (Extruded)

- Less expensive

- Better suited for bonding

Processing of PLEXIGLAS®

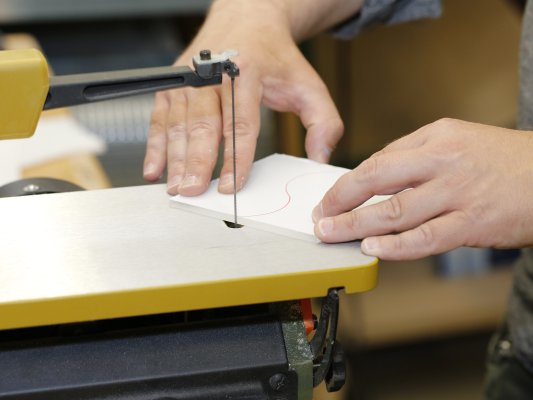

PLEXIGLAS® can be processed in many ways. Scoring is suitable for cutting up to a thickness of 3 mm. With this technique, you score the material with an acrylic cutter and break it over an edge. For thicker sheets, jigsaws and circular table saws (fine-toothed and possibly with cooling) or lasers are recommended. Drilling can be done cleanly using drill bits with an angle of 60-90° and little pressure. There are various options for bonding depending on the requirements (Ruderer, Acrifix, dichloromethane). Polishing with a special cloth and paste ensures a high lustre. Deeper scratches can be treated with wet sandpaper in grit sizes 320 - 400 - 600 - 1000.

Discover our cut-to-size world with customised PLEXIGLAS® sheets

In addition to PLEXIGLAS® sheets, we also stock acrylic glass in various other shapes. Discover tubes, rods, cubes and spheres. You can find even more information about the material in our materials library.

We also offer all of this in customised cuts. Discover the range here, which you can have cut to size and delivered directly to your home.