Translucent, non-colored impression silicone

Easy processing

High impression accuracy

Good price-performance ratio

| Article No. | |

|---|---|

| Material | addition-curing 2-component silicone rubber |

| Shore hardness | A 35 |

| color | colorless, translucent |

| Mixing ratio | 1:1 by weight |

| Specific weight | 1,07 |

| Viscosity | 7000 mPas |

| Mixing time at 23 °C | 1 min |

| Working time at 23 °C | 4 min |

| Curing time at 23 °C | 60 min |

| Tensile strength | 8.0 N/mm² |

| Dimensional change after 24 h | 0,1% |

| Elongation at break | 450% |

| Short-term temperature resistance | -60 °C to +250 °C |

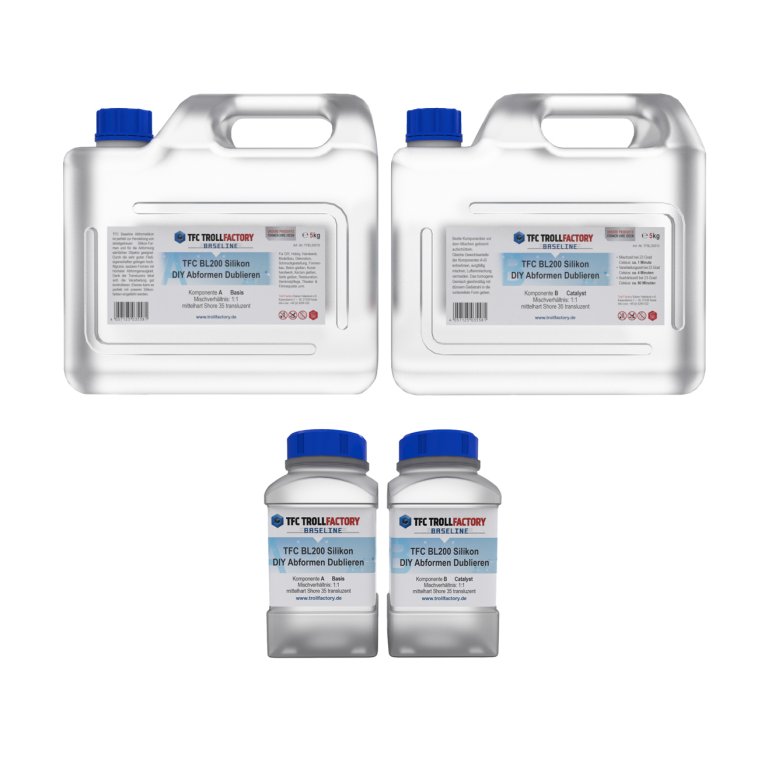

Would you like to try your hand at working with impression silicones and are looking for a good way to get started? You have found it with the TFC silicone rubber Baseline 200 (BL200). The product focuses on the essentials to offer you an attractive price-performance ratio.

The silicone is slightly thinner than comparable products, but thanks to its good flow properties, it enables a delicate and detailed impression to be made. The pot life and curing time are somewhat shorter. The A-component of the silicone is not colored. Although this means that you have to be careful when mixing the two components, it offers you the advantage of being able to color the silicone to your liking.

Thanks to its high inherent stability, the molding silicone is suitable for producing larger, durable, elastic molds for water-soluble or solvent-based casting compounds. You can use it for molding wood, glass, metal, plastic, wax and ceramic casting compounds.

And this is how it works

Shake both components well. Mix component A and component B together carefully in equal parts. Take care to avoid mixing in air. Pour the mixture into the prepared mold with an even, thin stream.

Important

Please note that the silicone has not been tested for skin and mucous membrane compatibility or for use with food.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Translucent, non-colored impression silicone

Easy processing

High impression accuracy

Good price-performance ratio

| Article No. | |

|---|---|

| Material | addition-curing 2-component silicone rubber |

| Shore hardness | A 35 |

| color | colorless, translucent |

| Mixing ratio | 1:1 by weight |

| Specific weight | 1,07 |

| Viscosity | 7000 mPas |

| Mixing time at 23 °C | 1 min |

| Working time at 23 °C | 4 min |

| Curing time at 23 °C | 60 min |

| Tensile strength | 8.0 N/mm² |

| Dimensional change after 24 h | 0,1% |

| Elongation at break | 450% |

| Short-term temperature resistance | -60 °C to +250 °C |

Would you like to try your hand at working with impression silicones and are looking for a good way to get started? You have found it with the TFC silicone rubber Baseline 200 (BL200). The product focuses on the essentials to offer you an attractive price-performance ratio.

The silicone is slightly thinner than comparable products, but thanks to its good flow properties, it enables a delicate and detailed impression to be made. The pot life and curing time are somewhat shorter. The A-component of the silicone is not colored. Although this means that you have to be careful when mixing the two components, it offers you the advantage of being able to color the silicone to your liking.

Thanks to its high inherent stability, the molding silicone is suitable for producing larger, durable, elastic molds for water-soluble or solvent-based casting compounds. You can use it for molding wood, glass, metal, plastic, wax and ceramic casting compounds.

And this is how it works

Shake both components well. Mix component A and component B together carefully in equal parts. Take care to avoid mixing in air. Pour the mixture into the prepared mold with an even, thin stream.

Important

Please note that the silicone has not been tested for skin and mucous membrane compatibility or for use with food.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.